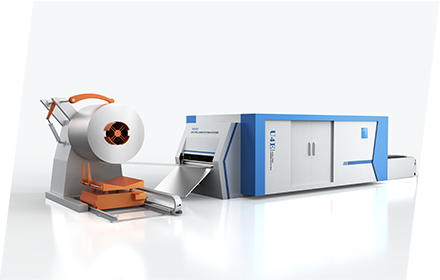

OVERVIEW OF U3E MODEL

COIL FED LASER CUTTING SYSTEMS

U3E applies to standard metal coils. Upon decoiling and flattening,materials are delivered to the cuttingunit for feeding and cutting through the special machine tool structure and output via the transmission platform for sorting and unloading.

Fully automated process minimizing operator requirement and allowing continuous and unattented production.

Reegao are able to match any material specification and any coil size, using our home made equipment.Reegao strong engineering department allows to match many coil line configuration as well as part sorting solutions to comply with customer factory needs and environement.Reegao offers turnkey systems for coil processing, all equipment from a single source.

Reegao offers turnkey systems for coil processing, all equipment from a single source.Core advantages

With help of the blow advantages,we can achieve better coil processing.